Roof Panel Ho Etsa Mochini oa Marula oa Lebota Lakane oa Ho Etsa Mochini oa Mochini o Habeli oa Glaze Steel Tile Roofing Sheep Make Machine

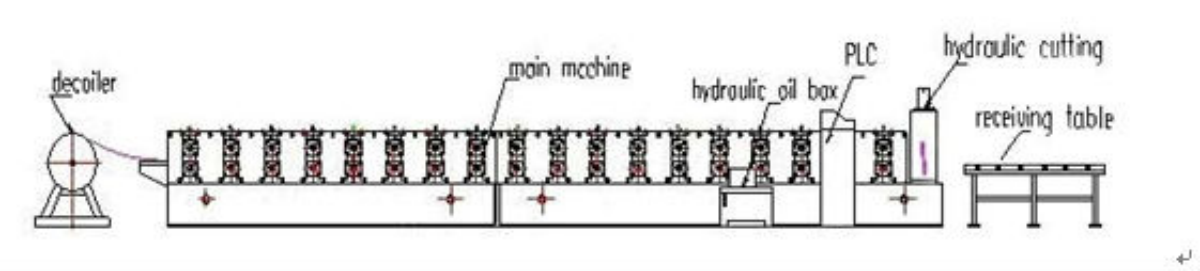

Litšoantšo tsa mochini

Mechini ea rona e ikemetseng ea ho etsa marulelo a tšepe e laoloa ke komporo, e netefatsa litekanyo tse nepahetseng le tse nepahetseng tsa phanele e 'ngoe le e' ngoe e hlahisoang.Mochine ona o sebetsa ka litsela tse ngata hoo o ka hlophisoang ho etsa mefuta e sa tšoaneng ea marulelo le mahlakoreng ho finyella litlhoko tse sa tšoaneng.Sebopeho sa ho fetola boholo ba mochini o ikemetseng se tiisa hore lakane ka 'ngoe e ts'oana, e tsitsitse ebile e na le boleng bo holimo.

E entsoe ka ho tšoarella kelellong, moetsi enoa oa li-shingle o hahiloe ho tšoarella.E entsoe ka lisebelisoa tsa boleng bo holimo le tse matla, mochine ona o etselitsoe ho mamella mathata a ts'ebeliso e tsoelang pele, e leng se etsang hore e be letsete le loketseng bakeng sa likhoebo tse hlokang ho hlahisa liphanele tse phahameng.

Mechini e etsang mapolanka a marulelong e na le mefuta e mengata ebile e bonolo ho e sebelisa.Mochine o sebetsa ka ho feletseng, ho bolelang hore o hloka ho kenella ho fokolang ha opereishene.Tšobotsi ena e boetse e etsa hore e sebetse hantle haholo kaha e ka hlahisa palo e kholo ea pampiri ka nako e khutšoanyane.

Ntho e 'ngoe ea bohlokoa ea mochini oa rona oa ho etsa lithaelese tse peli tsa fiberglass ke ho feto-fetoha ha oona.E khona ho hlahisa liphanele tsa marulelo a lithaele tse betliloeng habeli, mochini ona o loketse bareki ba hlokang botenya kapa meralo e khethehileng.Ho feto-fetoha ha mochini ona ho etsa hore e be khetho e phethahetseng bakeng sa likhoebo tse hlokang mefuta e mengata ea likhetho tsa tlhahiso ea pampiri.

Tlhaloso

| No | Ntho | Paramethara |

| 1 | Decoiler | 5tons decoiler ea motlakase (Hydraulic decoiler ka boikhethelo), buka e le 'ngoe mahala |

| 2 | Lebelo la ho theha | 12-18m/min |

| 3 | Lintho tse bonahalang | G235grade tšepe kapa galvanized coil |

| 4 | Botenya | 0.3-0.7mm |

| 5 | Ho theha mehato | 14 +13 ho etsa mehato |

| 6 | Shaft | Diameter 75mm, kaofela li tiile |

| 7 | Lirolara | Litšepe tse phahameng tsa 45 # tse nang le kalafo ea mocheso le ho roala chrome ka thata 0.04-0.05 |

| 8 | Sistimi e kholo ea foreimi | H350 tšepe.Ka ho qhomisa |

| 9 | Mofuta oa likoloi | shanghai lichao motor |

| 10 | Matla a ka sehloohong a ho etsa | 5.5kw. |

| 11 | Matla a Seteishene sa Pompo | 4Kw, kapa ho seha motlakase bakeng sa 3kw |

| 12 | Mofuta oa ho Seha | hydraulic cut or electric cutting |

| 13 | Lehare la ho Seha | Cr12Mov ka kalafo e thata, HRC52-68 |

| 14 | Sistimi ea Taolo | Delta PLC, skrine ea ho ama, converter ea maqhubu |

| 15 | Ho lekanya ho nepahala | Precision +/-1.5mm, ka converter frequency |

| 16 | Phetiso | Ka ketane e le 'ngoe 1' |

| 17 | Litekanyo tsa Mochini | Hoo e ka bang 7.5*1.5*1.7m |

| 18 | Boima ba mochini | Hoo e ka bang 5500 kgs |

| 19 | Palo ea li-volts | 380V,50hz, 3phase, joalo ka kopo |

MOTS'EPO MOTS'OANE

Decoiler

1. Bokhoni: e jara 5tons .

2. Boitsebiso ba coil bophara ba ka hare: 450mm-550mm

3. Bophara bo boholo: 1250mm

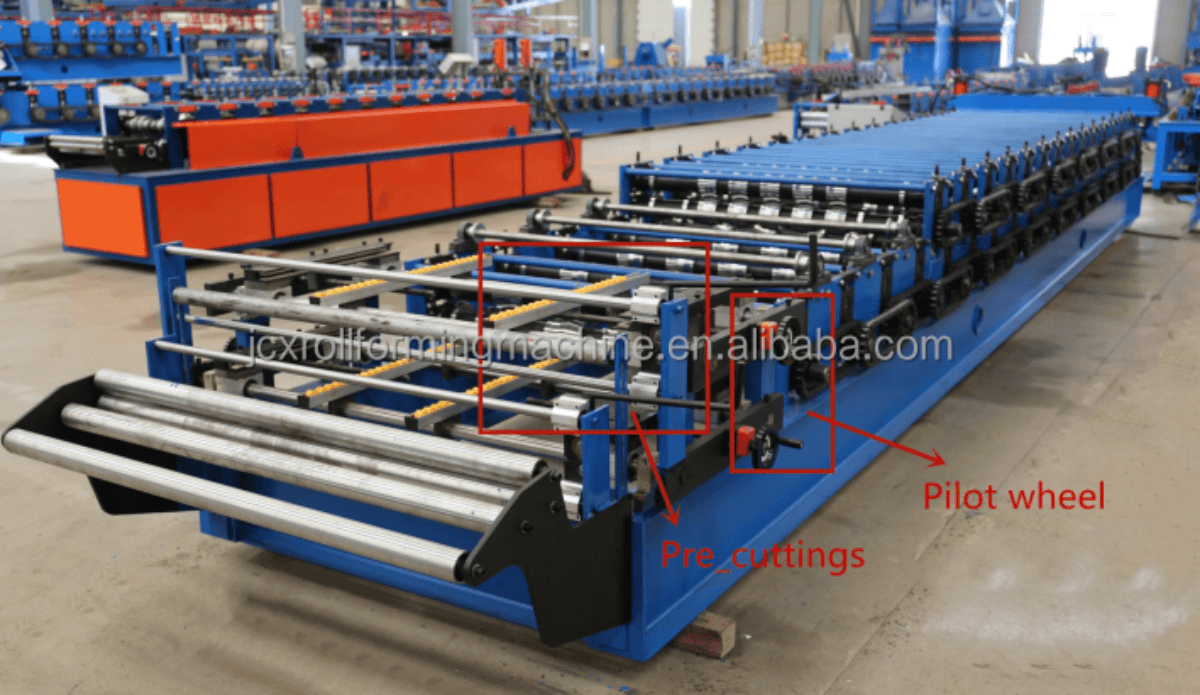

Sesebediswa sa Tataiso

1. Sesebelisoa sa tataiso se tsoetseng pele, etsa bonnete ba hore moqolo oa tšepe o tsamaea ka tsela e nepahetseng.

2. Mekhahlelo e 'meli kaofela e na le lisebelisoa tsa ho itšeha pele, boloka tšepe ea tšepe, ha ho na litšila.

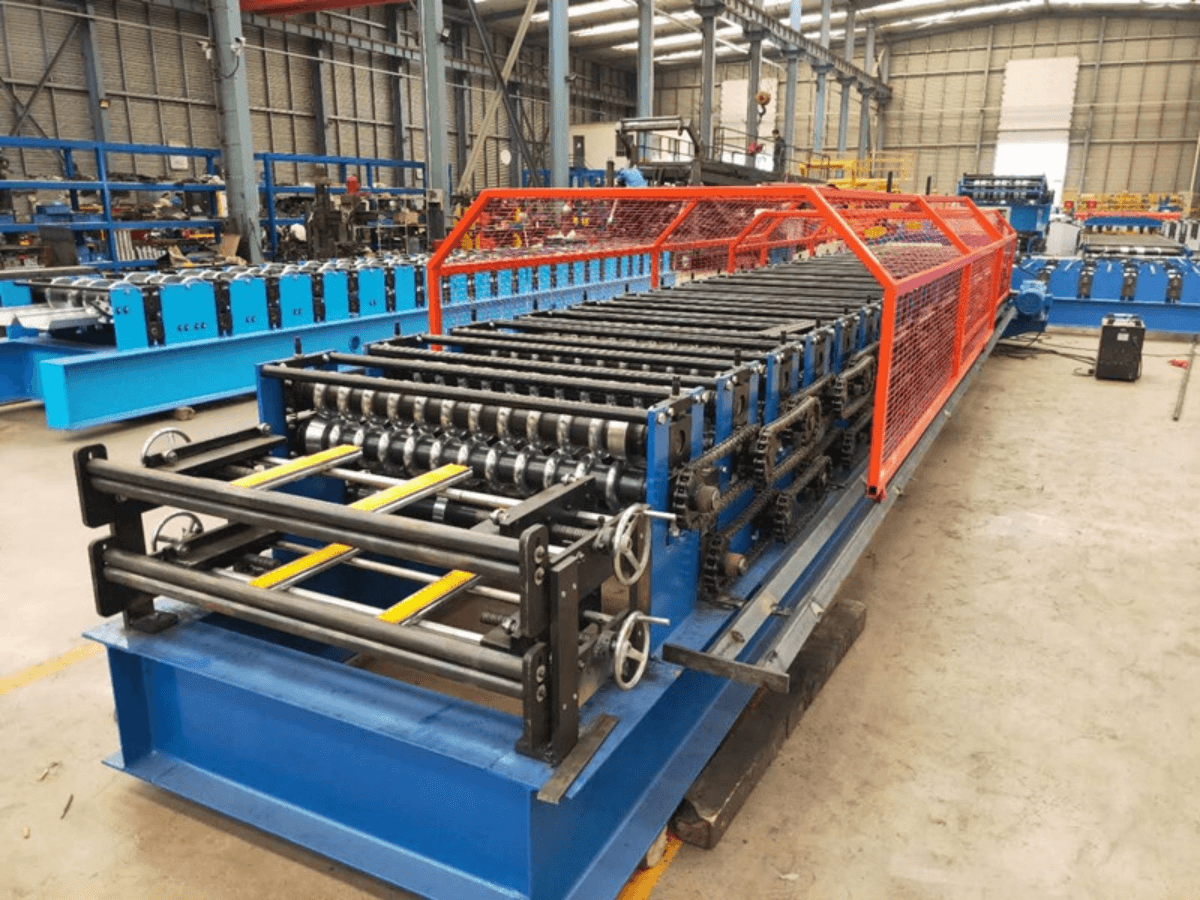

Mochini o ka Sehloohong oa ho Etsa

Sheba litekanyo tsa mochine

Hydraulic Cutting

Sistimi ea ho itšeha ka Hydraulic - Mofuta oa litšiea tsa Tataiso kapa ho seha Motlakase.Ho potlaka ho feta

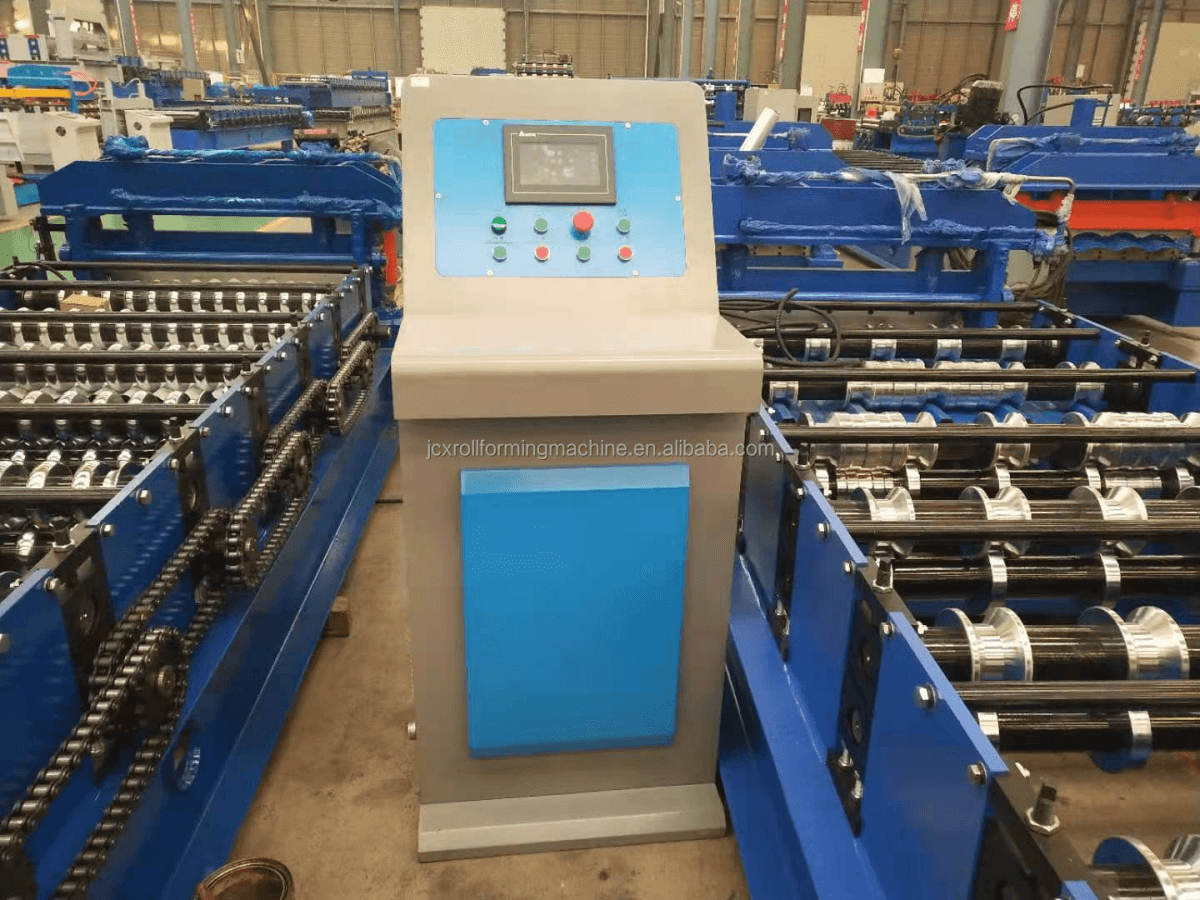

Sistimi ea Taolo

1).Screen: Delta

2).PLC: Delta

3).Tekanyo ea bolelele bo itekanetseng

4).Tekanyo ea bongata e iketsang

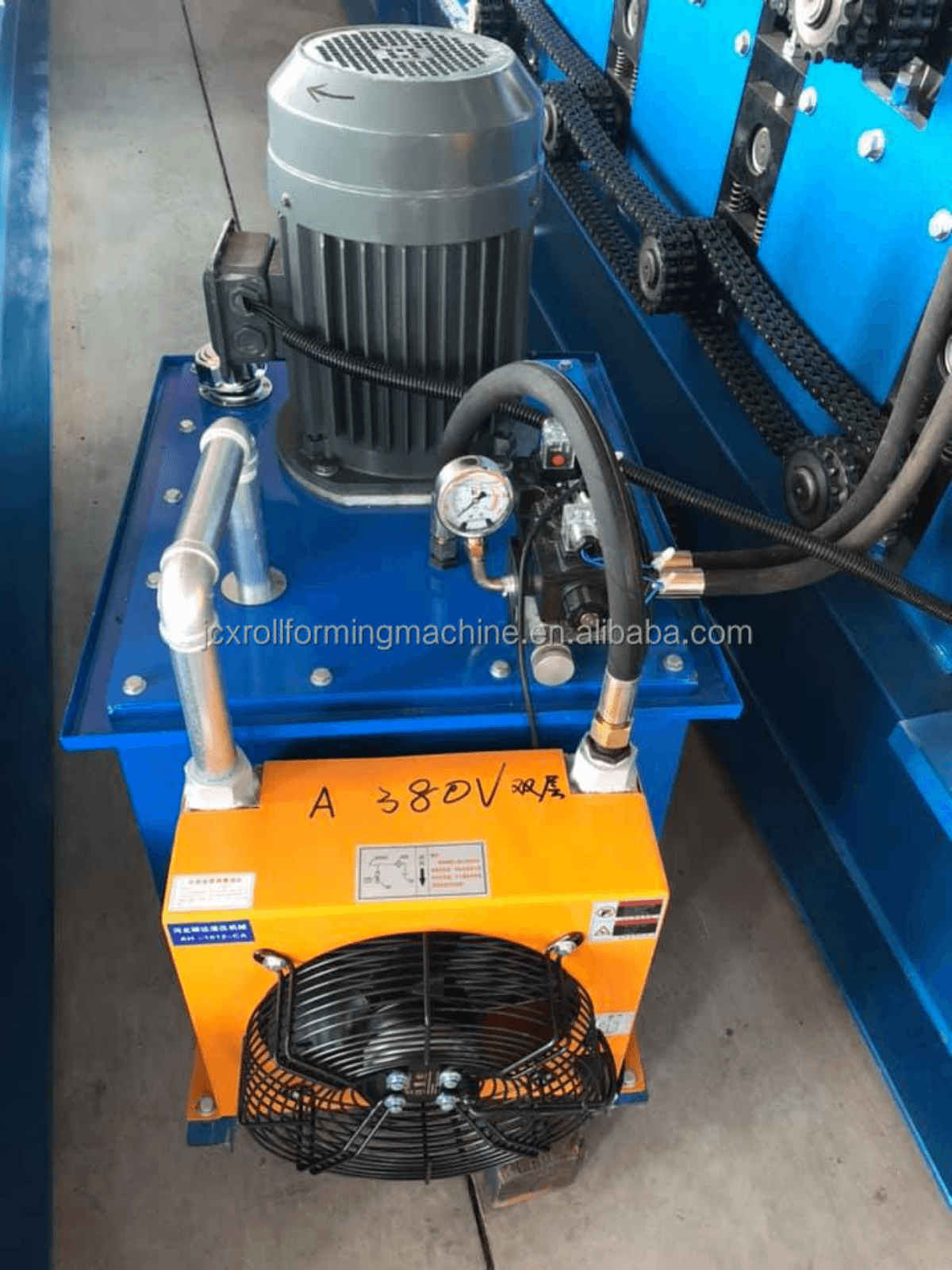

Seteishene sa Hydraulic

1).Amohela sistimi e tsoetseng pele ea hydraulic, e nang le fan e pholisang.

2).Motlakase: 4kw

3).Oli ea Hydraulic: 46 #

Kopo

Ho paka & Delivery

1. Mochini o le mong o ka kenngoa ka har'a setshelo se le seng sa 40GP.

2. Mechini eohle e tla lekoa pele e tlisoa

3. Re tla u romella buka ea matsoho le video e sebetsang ka mechini.

4. Likarolo tsohle tse setseng li tla kenngoa ka lebokoseng le le leng la lisebelisoa.

Boemo ba Khoebo

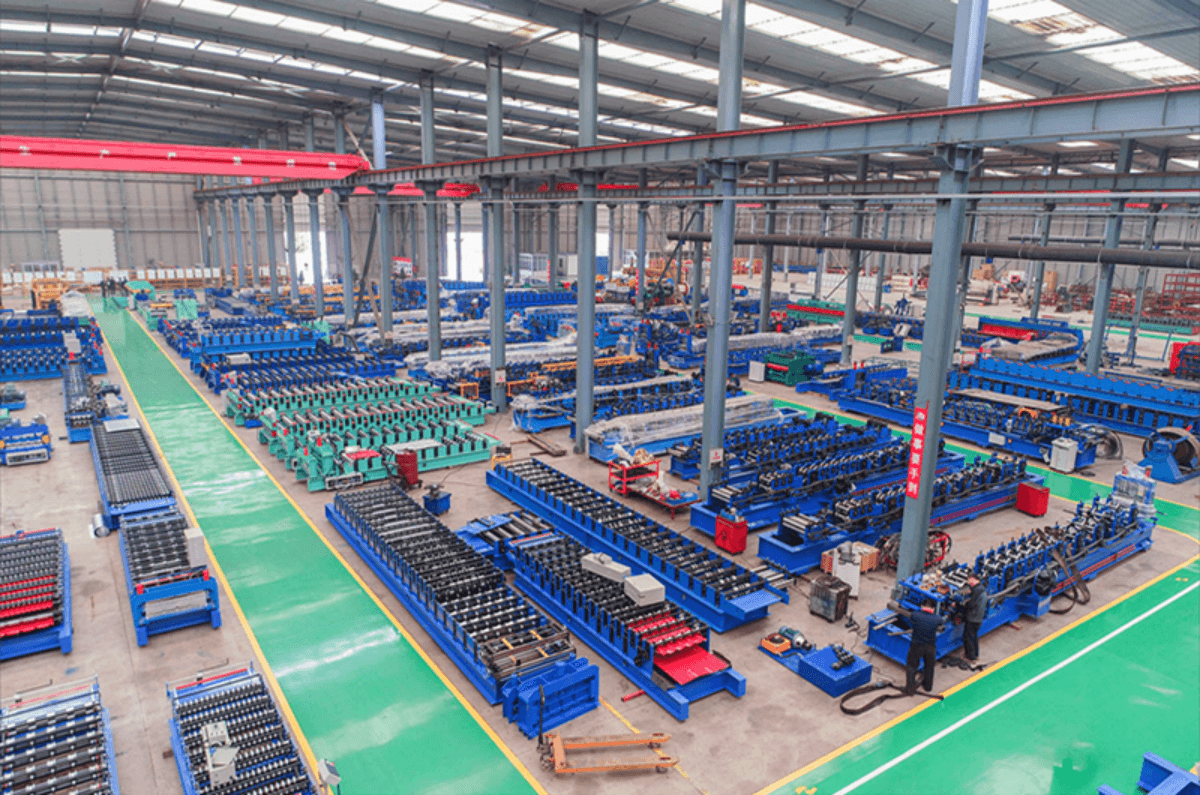

Botou Golden Integrity Roll Forming Machine Factory e teng "toropong ea ho lahla hlobo", e natefeloa ke lipalangoang tse bonolo le tse sebetsang haholo bakeng sa ho ba haufi le Tianjin Port, No.104 National Way, No.106 National Way le Jingjiu Railway.Motheong oa mechini e tloaelehileng ea ho etsa roll, re boetse re theha mochini o mocha oa mochini o etsang li-roll, marulelo le metjhini ea marako, metjhini e benyang ea lithaele, metjhini ea ho etsa lipoleiti tse behang fatše, lisebelisoa tse thibelang lebelo le phahameng, metjhini e bopang lithaele tsa mebala e habeli. , Mechini ea tšepe ea C le Z, lisebelisoa tsa arch, metjhini e kopantsoeng ea sandwich, metjhini e kutang, metjhini e kobehang, le metjhini e kopanyang ea sandwich ea mocheso.Lihlahisoa tsa rona li fihlile boemong bo tsoetseng pele indastering e tšoanang.E le ponahalo e ntle, sebopeho se utloahalang, le litekanyetso tse thehiloeng ho lithaele tsa lihlahisoa tsa rona, li tumme har'a bareki ba bacha le ba khale.Lihlahisoa li rekisetsoa likhoebo tsa malapeng.

LBH

1. Na k'hamphani ea hau e ka hlophisa boemo ba ka bo hlokahalang?

Ee monghadi/Mofumahadi.Mechini ea rona kaofela e entsoe ho latela litlhoko tsa bareki.Ke sa tsoa mpha setšoantšo sa hau se hlokahalang mme re ka u fa tharollo ea boqapi ba mochini oa rona.

2. Haeba ha ke na setšoantšo sa profil, empa ke batla ho reka mochini o le mong, na u ka nthusa?

Ho joalo sir/ Madam.Haeba ha u na litšoantšo tsa profil, litharollo li na le:

2.1 : Mphe linepe tsa profaele ea hau;

2.2 : Mpolelle naha ea heno 'me ke tla hlahloba hore na re rekisa mochini oa profil o tšoanang / o amanang le uena moo.Ke tla u buella

litšoantšo tse amanang le profil.

2.3 : Mpolelle tlhahisoleseling efe kapa efe eo u nang le eona, 'me ho tla nthusa ho hlakola lifaele tsa hau tse hlokahalang.ebe o a qotsa.

3. Melemo ea khampani ea hau ke efe?

Ee monghadi/Mofumahadi.Melemo ea rona e na le:

3.1: Re feme e kholo ea lilemo tse 16.Re na le boiphihlelo bo bongata ba ho rala le ho etsa mochini.Re ka u fa se molemohali

tharollo ea mochine.

3.2: Re qetile mokhoa oa tlhahiso.Le lihlopha tse fetang 20 tsa mechine ea CNC e ka tšehetsang mochine o mongata

ho etsa ditaelo le tiisetso ya thomello.

3.3 : Re na le lilemo tse 20 khoebo ea kantle ho naha boiphihlelo.Barekisi ba rona boiphihlelo bo bongata bo ka netefatsa hore o tla ba le

ho reka hamonate le tšebeliso ea mochini le boiphihlelo kamora ho rekisa.'Me u sebelisane le rona, u ka fumana lintlha tse eketsehileng mabapi le mochine, ho kenyelletsa le mathata ao u ke keng ua a nahana empa re ka nahana ka ona, re ka u bolella ho etsa bonnete ba hore u ka reka mochine o loketseng ka ho fetisisa bakeng sa hau.

3.4 : Re k'hamphani e etsang mochini oa khauta e tšepahalang.Mabapi le lits'ebeletso tsa kamora thekiso, ha ho na matšoenyeho, re tla ikarabella bakeng sa hau.

4. Na ke tla fumana mochini o motle?E tšoanang le eo ke e batlang?

Ee monghadi/Mofumahadi.Re tla etsa mochini ho latela setšoantšo sa hau sa profil.Mabapi le setšoantšo sa profil, re tla netefatsa le uena hape pele re hlahisa mochini oa hau.Joale, ka mor'a hore mochine o qete, re tla leka mochine mme re tiise hore mochine oo u o fumaneng ke mochine o motle.Hobane ka mor'a hore u khotsofatsoe ke mochine, ebe u lefa tekanyo.

5. Bonyane palo ea mochini ke eng?

Mochini o le mong o lokile.

6. Lipehelo tsa hau tsa tefo ke life?

6.1 : Re amohela 30% T / T e le deposit le 70% T / T e le tekanyo pele re romelloa.

6.2 : Re amohela 100% L / C ha re bona

6.3: Re amohela litefo tsa Western Union.

6.4 : Lipehelo tse ling tsa tefo tseo u batlang ho li lefa, ke kopa u ntsebise, 'me ke tla u hlahloba ke be ke u arabe.

Tshebeletso

Tšehetso e Molemo ea Theknoloji

Khampani e 'nile ea ameha ka ho teba indastering ka lilemo tse fetang 10,' me e na le mahlale a 12 a netefalitsoeng naheng ka bophara ho theha litekanyetso tse 82 tse thata tsa ts'ebetso, le ho theha letoto la libopeho tsa boleng bo holimo, tsa maemo a holimo le tsa maemo a holimo. thepa.Ts'ehetso ea rona ea tekheniki e ka u fa lintlha tse qaqileng tsa sehlahisoa, mantsoe a qotsitsoeng ka nako ea nnete, le mekhoa ea 'maraka,' me ra u etsetsa lihlahisoa tse ntle ho latela litlhoko tsa sehlahisoa seo u fanang ka sona.

Tšebeletso ka mor'a thekiso ea molumo

Kamehla re beha lithahasello tsa bareki ba rona pele, re tseba hore katleho ea rona e itšetlehile ka katleho le tsoelo-pele ea hau.'Me u kenye mohopolo ona khokahanyong e' ngoe le e 'ngoe ho tloha ho moralo ho isa litšebeletsong tse rekisoang ka mor'a thekiso, e le hore lihlahisoa tsa rona li ka thusa bareki ho fokotsa litšenyehelo le ho ntlafatsa tlholisano.Re mamela ka hloko litlhoko le litlhoko tsa moreki e mong le e mong.Rala le ho etsa lihlahisoa ho latela litlhoko tse fapaneng tsa bareki ba fapaneng ho u thusa ho fumana lisebelisoa tse loketseng.